Unpacking Packaging Innovations & Empack 2026

Couldn't make it to the NEC? Here are our key takeaways from the two-day event.

An early train to Birmingham International. Two days at the NEC. Over 450 exhibitors across multiple halls showcasing the latest in packaging, plus a packed programme of talks on supply chain, design, and the circular economy. Day one drew strong footfall. The atmosphere was anticipatory, almost restless. Attendees came from across the country—one had travelled down from Scotland—though expectations were measured. "It's not often you see game-changing innovation in packaging," they told us. "A lot of the materials and technology has been around for a few years." True, perhaps. But the pressure to find solutions was palpable, particularly around the need to move away from plastics.

Sustainability dominated the conversation

Sustainability signalling was inescapable. Cardboard structures, nature-inspired imagery, an abundance of eco-messaging—every stand had it. An entire stage was dedicated to the Circular Economy, with two full days of talks.

The regulatory landscape is tightening. EPR (Extended Producer Responsibility) is rolling out across Europe, requiring producers to fund the recycling of their packaging waste. Plastic Packaging Tax has been with us since 2022, adding significant cost for companies using non-recycled plastic. More legislation is coming, and businesses unprepared to adapt will feel it.

The event showcased a huge focus on eco-solutions and plastic alternatives: cardboard, honeycomb, all-paper void fill cushioning. But it's not as simple as Plastic = Bad, Cardboard = Good. One stand determinedly proclaimed 'Rethinking Plastic' in its tagline.

As a Sustainability Lead we spoke at the event explained: "Plastic isn't the core issue. It's how we handle plastic. We invent the car, we don't think of the emissions. We invent plastic bottles—fantastic solution—we don't think of waste. You need to think of sustainable, efficient materials that reduce material, reduce weight, and then how you deal with that afterwards."

But complexity lurks beneath the surface. The same Sustainability Lead highlighted a critical challenge: "This is an industry that loves long supply chains, and when your data starts becoming opaque, you suddenly find out that your client's client's client might be paying EPR on their product, but you assume they're not, and you pay EPR too. Suddenly everyone's paying EPR." Transparency is the hidden issue.

So who's driving the shift? An exhibitor was candid: "Most brands are moving away from plastic due to plastic tax. Governments are pushing it. We're trying to stay in line. They're trying to stay in line." The price objection is fading. "It used to be seen as more expensive to go plastic free," another exhibitor explained. "Now with plastic taxes, it's going the opposite way. It's actually becoming cheaper to specify sustainable alternatives."

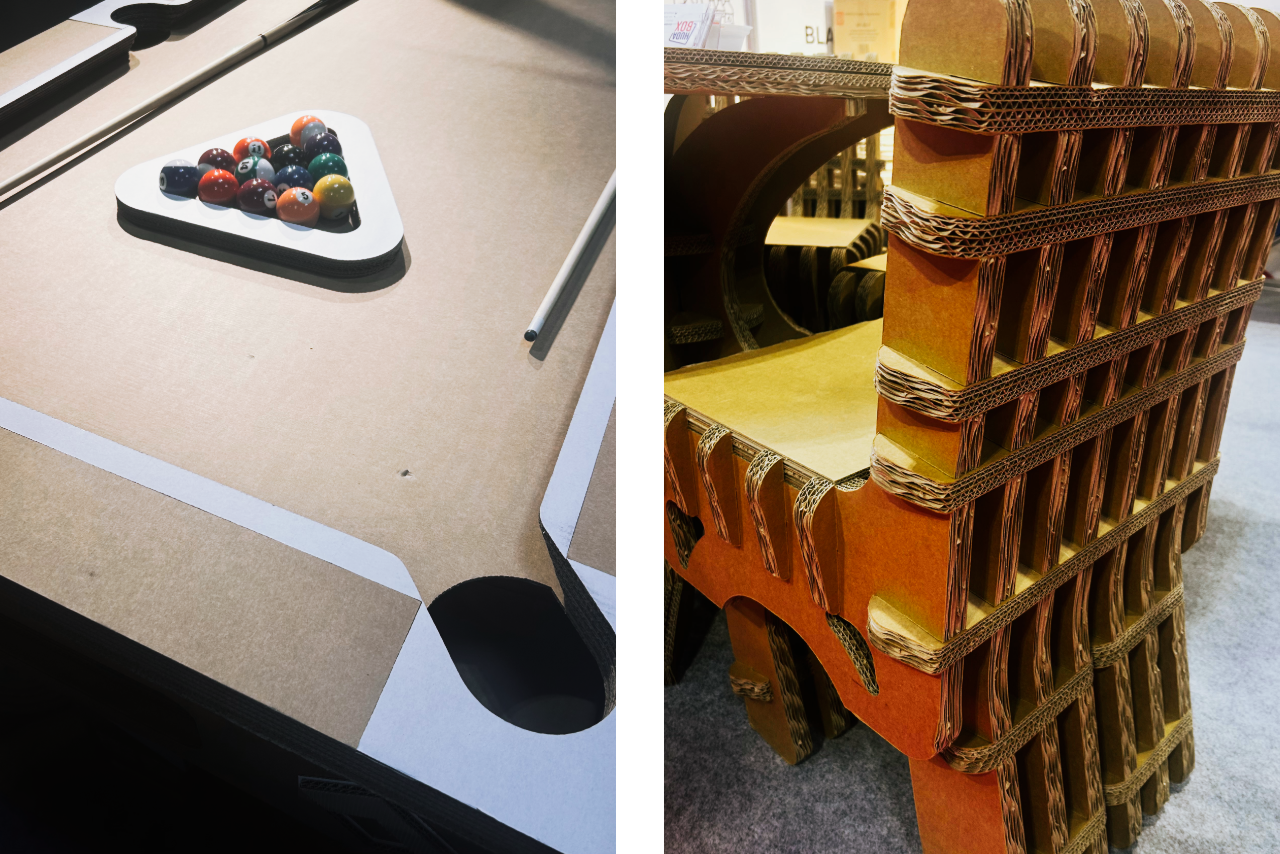

Cardboard proved its strength

Cardboard's rigidity was on full display. Large tree structures acted as focal points. Full-sized American pool tables demonstrated load-bearing capacity. The message: cardboard isn't just for boxes anymore.

Honeycomb material stole the show. You need less of it compared to traditional plastic airbags or bubble wrap. It's more pliable, moulding around products naturally. It acts as a shock absorber, securing items without filling every void, and can reduce breakages by up to 60%. All-paper cushioning showed remarkable versatility—crumpled for soft protection, folded for structure, layered for extra cushioning. And honeycomb is made from recycled material. If it escapes normal recycling processes and ends up as fugitive waste, it breaks down naturally.

There's a reputation issue at stake too: getting packaging right reduces breakages and returns. Damaged products hit both bottom line and brand reputation. Sustainable shipping bags for eCommerce also featured prominently—100% recycled material, eco-friendly alternatives across the entire packaging journey.

The Innovation Gallery sparked ideas

The Innovation Gallery was a big draw at the event. It showcased the latest in leading-edge solutions, with visitors voting for favourites. Standouts included a next-generation moulded fibre tray engineered for universal fit—protecting glass bottles during storage and transport with an adaptive 3D structure and integrated buffer zones. The logistics-ready, eco-responsible design reduces packaging costs and optimises storage without compromising performance.

Another innovation: a linerless tamper-evident bag closure that seals takeaway and delivery bags in one quick step, preventing open-bag complaints, reducing refunds, and protecting order integrity. Supplied on a roll with no backing liner, it speeds up packing while cutting waste.

Three stages delivered valuable insights

We spent most of our time at the Circular Economy stage. The programme included a pre-lunch discussion with Alison Bramfitt, Head of Packaging at Nestlé, exploring how to design packaging that actually gets recycled in the real world, and what it takes to build recyclability in from day one.

Over lunch, Steve Lister—Stage Chair and Sustainability Expert for Global Brands, Retailers & Supply Chain Partners—offered a refreshingly honest assessment of where the industry stands. The transformation has been dramatic, he explained, but easy to overlook. "You've only got to walk around this hall, and virtually all of what you see is fibre-based honeycomb board. If you go back 10-20 years, it was all PVC. But we forget that."

The shift hasn't come from one breakthrough moment. "There's been loads of incremental steps, not one big monumental one," Lister said. "So we've got used to the small changes." But those incremental steps add up. Materials have changed dramatically, driven not by altruism but by necessity—businesses now have to worry about what happens to packaging at end of life.

Lister was particularly emphatic about where the real impact lies. Material choice matters enormously: "80% of the carbon footprint of anything we make within print or packaging is material-based." But efficiency matters too. Companies that can reduce pallet counts by half, that stop shipping air, those are the ones that will win.

The persistent myth that sustainable alternatives cost more? Lister was optimistic. "We're finding a lot more materials now are at price parity," he said. Research he's been involved in shows many new sustainable alternatives are either price parity or cheaper than their oil-based predecessors. "So it blows that whole myth that sustainable materials are more expensive."

His final advice was refreshingly straightforward. "I think people just got to realise that it's not actually that complicated. There are probably small businesses that are more sustainable than they think they are." Ask your supplier to show you new materials. You'll be inundated. "Take one step at a time. Don't take a quantum leap. Just do something."

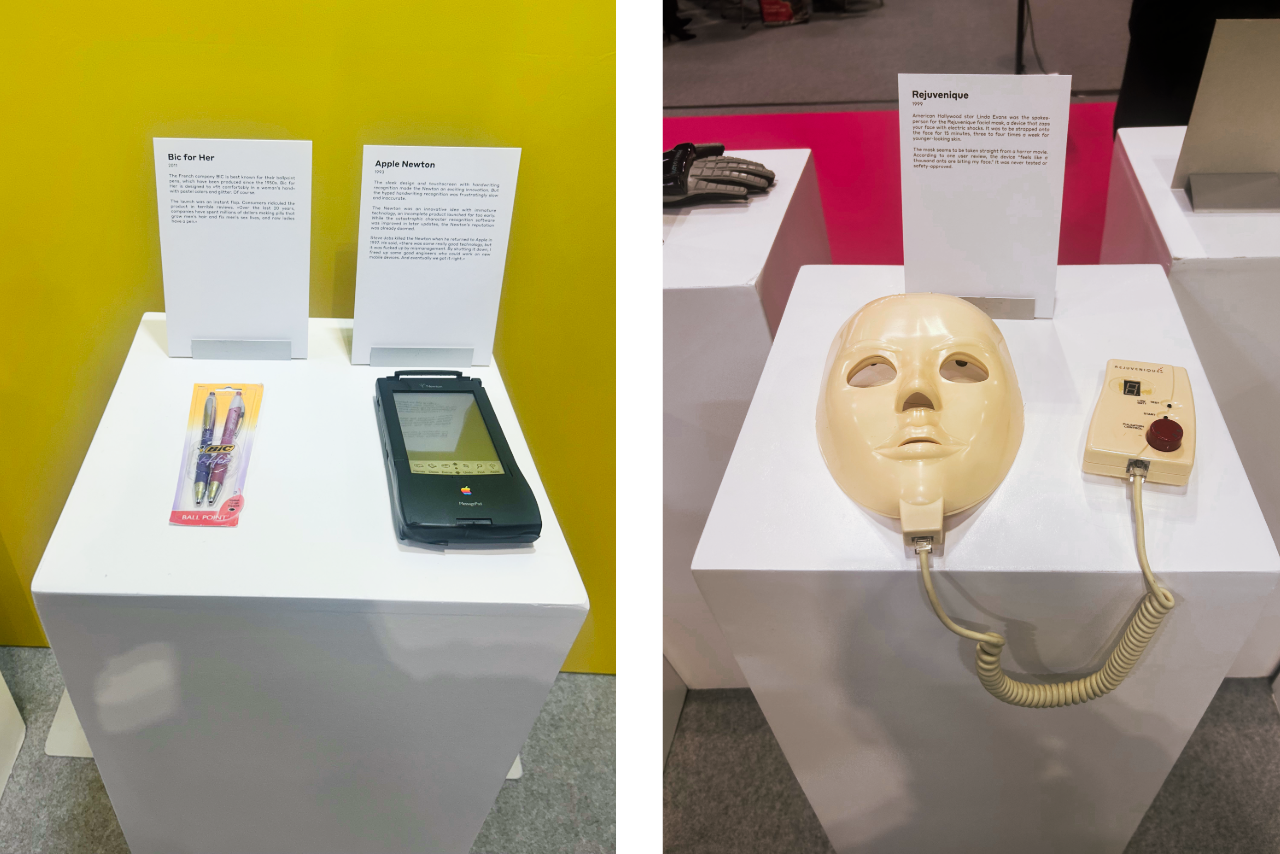

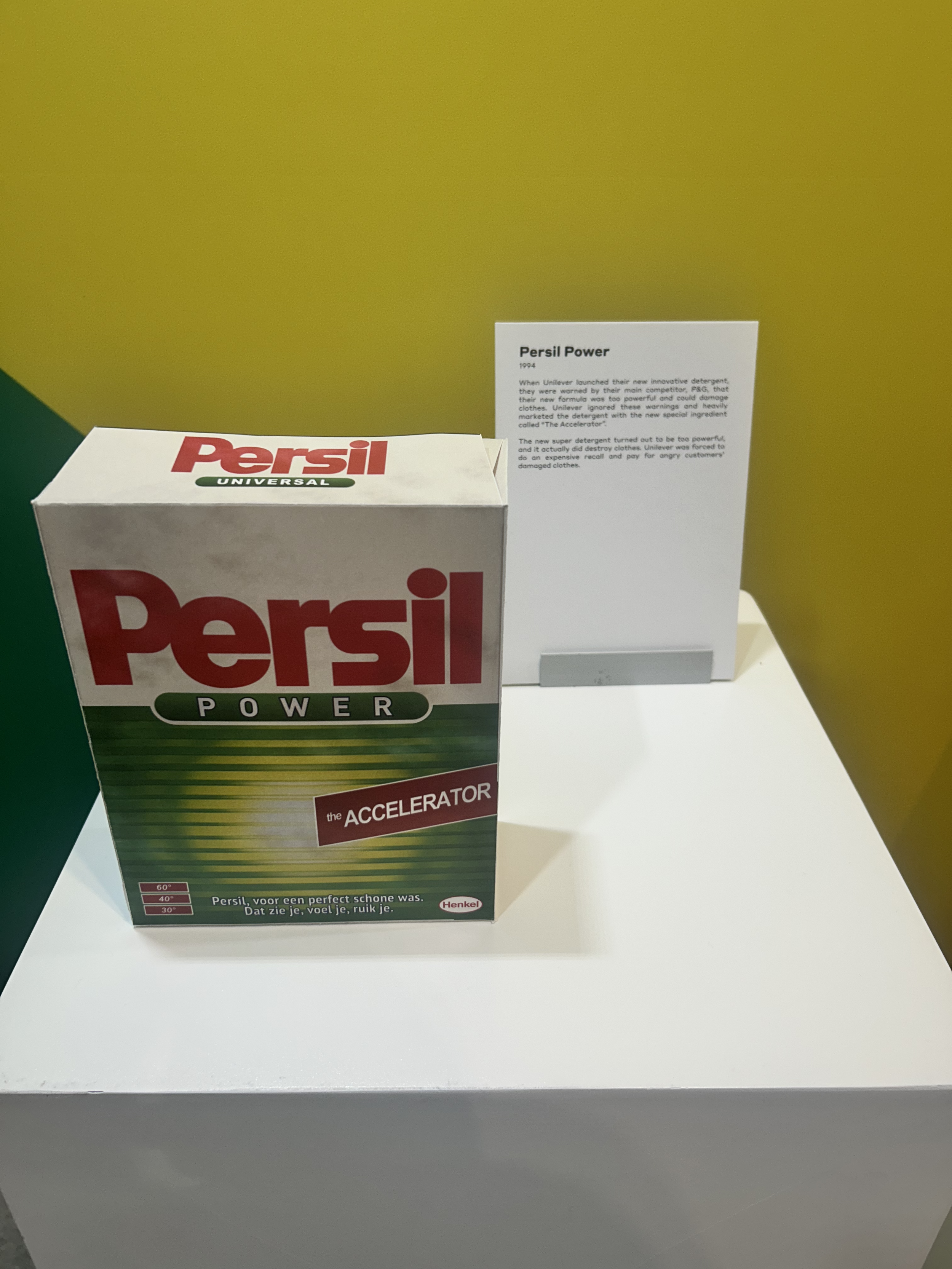

The Museum of Failure was a highlight

This was one of the must-see spaces at the event. Carefully curated examples of seemingly great innovations that didn't quite work—actual products on display. From the Apple Newton and Nintendo Power Glove to the bizarre, almost dystopian Rejuvenique facial mask. Innovation needs failure. All progress is built on learning from past mistakes, and the museum provides unique insight into the tricky business of innovation in packaging.

The standout? Frito-Lay SunChips packaging. It plant-based, 100% biodegradable packaging might have ticked the sustainability box, but it registered a less than quiet packet rustle of 95 decibels when handled. "Sorry but I can't hear you over the sound of the bag" is not a winning formula. An audio demo booth let you experience it: trust us, It was loud. Unsurprisingly, within six months, Frito-Lay pulled the compostable bags and reverted to traditional non-recyclable plastic.

The lesson: innovation requires balance. Sustainability credentials alone aren't enough if packaging doesn’t work in the real world.

Final takeaway

Packaging Innovations & Empack 2026 showcased our industry in transition. Sustainability isn't just a buzzword anymore—it's becoming baseline expectation. The materials are evolving, the economics are shifting, and the legislation is tightening.

What struck us most was the pragmatism. No grand gestures or impossible targets. Just incremental progress, price parity, and practical solutions. As Steve Lister said: Just do something.

The industry is ready. The materials are there. The question now is whether businesses will adapt quickly enough to stay competitive in a market moving away from plastic, one honeycomb board at a time.